A-ComP Präzisionspressen von Endkontur-genauen Formteilen

Das automatisierte, endkonturgenaue x-NET Fertigungsverfahren von CrossTEQ ermöglicht die gezielte Nutzung von mechanischen Eigenschaften in komplexen Leichtbaustrukturen.

Sie benötigen einbaufertige Leichtbauteile mit aussergewöhnlichen Material- und Oberflächeneigenschaften?

Mit der x-NET Compression Molding Technologie produzieren wir Formteile mit komplexen 3D-Strukturen in kleinen und grossen Serien. Kontaktieren Sie uns, um mehr zu erfahren.

Über x-NET Precision Compression Molding von CrossTEQ

CrossTEQ hat ein automatisiertes, endkonturgenaues Fertigungsverfahren entwickelt, das die gezielte Nutzung von mechanischen Eigenschaften in komplexen Leichtbaustrukturen ermöglicht.

X-NET Precision Compression Molding is a proprietary composite production technology from CrossTEQ, as it is based on an advanced precision molding process for carbon parts originally developed for aerospace applications.

X-NET kombiniert für Sie die Produktdesignfreiheit und den Automatisierungsgrad der Spritzgusstechnik mit den hervorragenden Materialeigenschaften der thermoplastischen Faserverbundwerkstoffe.

Top-Features von x-NET Präzisionsbauteilen

Mittels der x-NET Formpresstechnologie stellen wir hochwertige, konturgenaue Composite-Bauteile mit höchster Funktionsintegration, feinsten Toleranzen und minimalem Materialverschnitt bei guter qualitativer Wiederholbarkeit her.

- Leichtgewicht

- Leistungsstark dank konstruierten Eigenschaften

- Funktionale Oberflächen

- Einzigartige Ästhetik mit bester Oberflächenqualität

- Recyclierbar

Wieso Hochleistungs-Composites für komplexe Leichtbaustrukturen?

Thermoplastische Faserverbundwerkstoffe werden aufgrund Ihrer hervorragenden Materialeigenschaften dort eingesetzt, wo Metalle wie Stahl oder Titan zu schwer und Kunststoffe zu schwach sind.

Dabei sind Faserverbundverfahren für Flächen heute vergleichsweise ausgereift und in zahlreichen Anwendungen wie Flug- und Fahrzeugstrukturen breit etabliert. Composite-Technologien für komplexere Strukturelemente wie z.B. Verbindungs- oder Lasteinleitungselemente sind bisher hingegen wenig ausgereift. Leicht- und Maschinenbau warten noch auf skalierbare Lösungen für ihre Hochleistungs-Anwendungen.

Verbindungselemente: Wo selbst Stahl und Titan an ihre Grenzen stossen

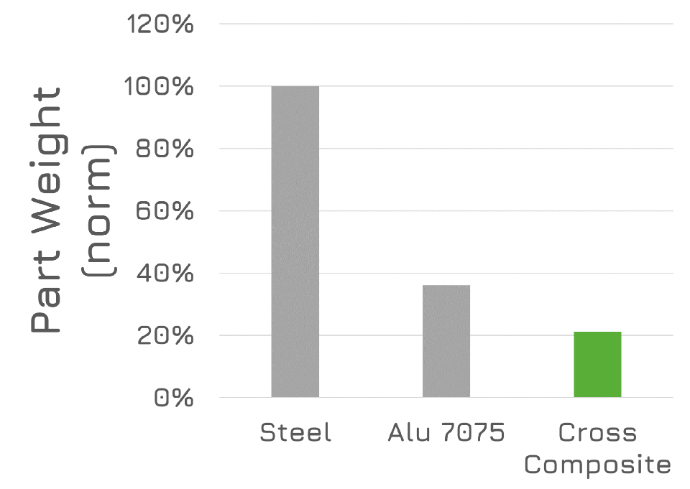

Aufgrund ihrer geometrischen Komplexität werden für Verbindungselemente wie zum Beispiel Clips, Brackets oder Hinges werden nach wie vor meist metallische Werkstoffe wie Stahl, Titan oder Aluminium verwendet. Diese Materialien weisen in Leichtbauanwendungen allerdings wesentliche Nachteile auf:

- Stahl: Hohes Gewicht aufgrund hoher Dichte

- Titan: Hohe Material- und Bearbeitungskosten aufgrund niedriger Verfügbarkeit des Rohmaterials

- Aluminium: Hoher Prozessaufwand zum Aufbau von Korrosionsschutz gegenüber umliegenden Composite-Strukturen

Gezielte Nutzung der hervorragenden Materialeigenschaften von thermoplastischen Composites

Mit dem Ziel, komplexe und zugleich leistungsstarke Leichtbaustrukturen automatisiert herzustellen, hat CrossTEQ ein eigenes, endkonturgenaues Composite-Verfahren entwickelt, das die Folgeprozesse, der Materialverschnitt und somit auch die Kosten bei der Bauteilherstellung auf ein Minimum optimiert.

Mit x-NET kombiniert CrossTEQ die Produktdesign-Freiheit aus der Spritzgusstechnik mit den hervorragenden Eigenschaften der thermoplastischen Composites und bietet dem Leicht- und Maschinenbau damit ein skalierbares Produktionsverfahren für die Herstellung von endkonturgenauen Verbindungselementen und Profilen aus faserverstärkten Hochleistungs-Kunststoffen wie PEEK, PSU, PPSU oder PEI.

Die thermoplastischen x-NET Leichtbauteile von CrossTEQ, erreichen identische mechanische Eigenschaften wie Metalle - allerdings bei massiver Reduktion des Gewichtes.

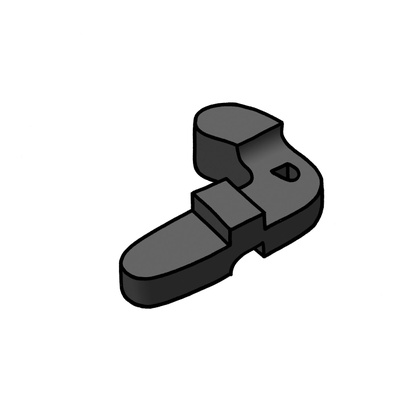

Geometrisch komplexe und funktionale Composite-Bauteile von CrossTEQ

Die thermoplastischen Faserverbundwerkstoffe von CrossTEQ ermöglichen vielseitige mechanische, chemische und tribologische Features, die wir mit unserer x-Net Produktionstechnologie gezielt für Ihr Präzisionsbauteil hervorrufen können.

Wall thickness increments

Reinforcing ribs

Threads

Inserts

Drillings

Undercuts

Bearing seats

Functional surfaces

Wieso x-NET Formpressen?

Automatisierte end-konturgenaue Fertigung von Präzisionsbauteilen

Thanks to final contour precision manufacturing, x-NET optimizes downstream processes, material waste and thus also costs during component manufacture to a minimum.

- Automatisierte Produktion für maximale Kosteneffizienz

- Höchste Funktionsintegration

- Maximale Materialausnutzung

- Feinste Toleranzen, minimaler Nachbearbeitungsaufwand

- Vollständiger Erhalt der Fasereigenschaften

- 0% Verschnitt

Prototypen- bis Serienfertigung

Mit der x-NET Compression Molding Technologie produzieren wir endkonturgenaue, einbaufertige Composite-Bauteile in allen Seriengrössen:

- Prototyping (10 parts)

- Individual, special and replacement production

- Medium series production (100 parts)

- Industrial production (10'000+ parts)

Unendliche Material-Konfigurationen möglich mit x-NET Präzisionspressen

Wählen Sie aus unzähligen Composite-Bestandteilen und entdecken Sie unsere unendlichen Verbund-Möglichkeiten:

Our polymers:

PEEK, PES, PEI, PPS, TPI, PA6, PA66, PA12

Our reinforcing fibers:

Carbonfaser, Glasfaser, Basaltfaser, Naturfaser, andere auf Anfrage

The x-NET production process

STEP 1

Preparation

The composite material is manufactured according to the required specifications and material properties.

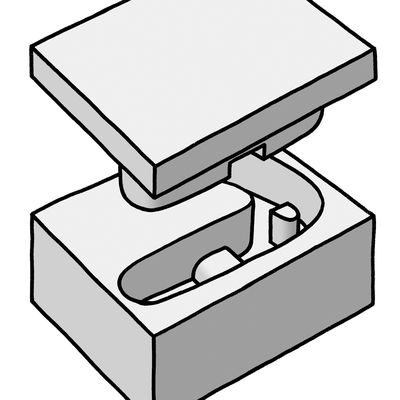

STEP 2

Processing

The composite material is processed with highly complex mould tools. Our mould tools are completely closed moulds with fully defined cavity surfaces, which enable the high-precision production of moulded parts.

STEP 3

1% post-processing

The finished composite part is removed from the mould. In this state, the component is 99% finished; only light deburring and polishing is still required.

Die x-Technologies in der Übersicht

Durch intelligentes Material Design und mit der richtigen Composite Technologie zu den optimalen Features für Ihr Leichtbauteil.

Unsere Cross-Composites bieten Ihnen vielseitige mechanische, chemische und tribologische Features, die wir mit unseren x-Technologies gezielt für Ihre Anwendung hervorholen können.