Smarte Composite Halbfabrikate

Mit der x-CONTOUR Technologie produzieren wir Lastpfad-optimierte Rohlinge aus thermoplastischem Faser-Verbundwerkstoff.

Sie benötigen Rohlinge mit einer spezifischen Faserorientierung?

Wir produzieren für Sie Lastpfad-optimierte Halbfabrikate, die Sie selbst einfach nachbearbeiten können. Teilen Sie uns Ihre Anforderungen mit – Gerne beraten wir Sie zu Ihren Möglichkeiten mit unserer x-CONTOUR Technologie.

Semi-finished products made of fiber composite material for own, simple post-processing

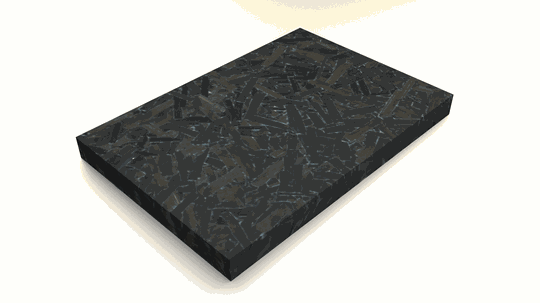

In addition to their special strength, the load-path-optimized fiber composite blanks are characterized by reduced material waste (cf. x-BLOC composite lightweight panels) during production.

The material can be machined into its final shape, and you can create several similar shapes and designs with one semi-finished product.

Top-Features of x-CONTOUR composite blanks

Realisierung von Lastpfaden

Increased strength due to specific fiber orientation

Reduced material waste

Mehrere ähnliche Formen in einem Rohling abbildbar

Eigene Nachbearbeitung

Eigene Nachbearbeitung

Using its proprietary x-CONTOUR composite production technology, CrossTEQ manufactures semi-finished products from thermoplastic fiber composite material.

The x-CONTOUR composite technology is based on the thermoplastic compression molding manufacturing process and enables the design of a specific fiber orientation and the targeted use of strength and stiffness in components.

The x-CONTOUR composite production process

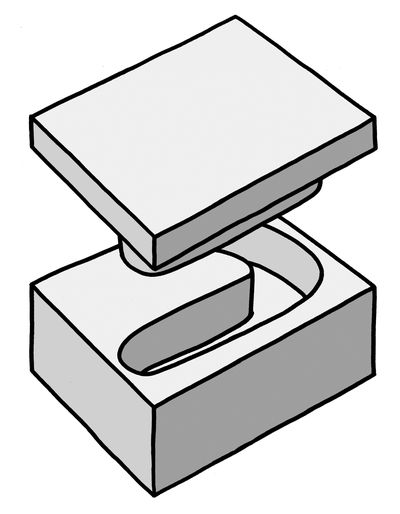

STEP 2

Processing

The composite material is processed using simple molds. Molding tools are completely closed molds with fully defined cavity surfaces that allow precise composite blanks to be produced for further processing.

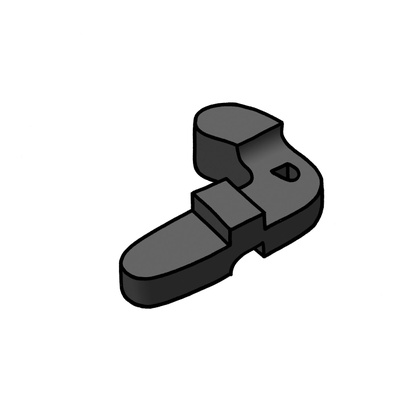

STEP 3

Blanks

A composite blank is demolded from the simple mold.

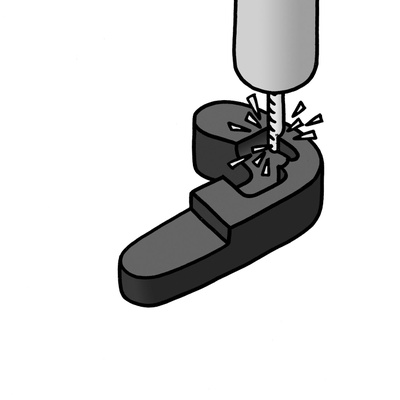

STEP 4

Post-processing

The blank is finished using machining processes such as milling and turning.

STEP 5

Finishing

After surface polishing and other finishing methods, the component is fully manufactured and ready for testing and packaging.

Our x-Technologies at a glance

Unsere Cross-Faserverbundwerkstoffe bieten Ihnen vielseitige mechanische, chemische und tribologische Features, die wir mit unseren anwendungsorientierten Composite Produktionstechnologien (x-Technologies) gezielt für Ihr Verbund-Projekt konstruieren und nutzen können.