A-ComP Compression Molding

The thermoplastic compression molding process combines the level of automation and product design freedom from injection molding with the high strength and rigidity of carbon fiber composite materials.

Was ist thermoplastisches Compression Molding?

In the thermoplastic compression molding process, material chips cut to size are scattered into a mold. The mold is then placed in the compression molding machine and pressed into the desired shape in various process phases. The entire process is controlled by pressure and temperature parameters precisely matched to the compression mold and content.

A-ComP Compression Molding: Thermoplastisches Formpressverfahren von CrossTEQ

Mit A-Comp Compression Molding bietet CrossTEQ ein kosteneffizientes Produktionsverfahren für die Herstellung von einfachen bis geometrisch komplexen Faserverbundbauteilen aus Hochleistungs-Kunststoffen.

Wieso A-ComP Compression Molding von CrossTEQ?

A-Comp ermöglicht die kosteneffiziente Produktion von Leichtbauteilen aus faserverstärkten Kunststoffen wie PEEK sowie auch PSU, PPSU oder PEI Kunststoffen in allen Seriengrössen:

- Automatisierte Composite Produktion

- Bis zu 50'000 Teile pro Jahr pro Produktionszelle

- Prototyping (10 Teile)

- Einzel-, Spezial- und Ersatzfertigungen

- Mittlere Serienproduktion (100 Teile)

- Industrielle Produktion (10'000+ Teile)

A-ComP Formpressen: Die richtige Technologie für Ihre Anforderungen

Mit unseren anwendungsorientierten Compression Molding Technologien fertigen wir sowohl einfache als auch geometrisch komplexe 3D-Composite-Bauteile. Dabei legen wir besonderen Wert auf die Integration spezifischer Materialeigenschaften und funktionaler Oberflächen, um den höchsten Anforderungen in verschiedenen Industrien gerecht zu werden.

Unsere innovativen Fertigungsverfahren ermöglichen es, maßgeschneiderte Lösungen zu produzieren, die nicht nur in ihrer Leistung überzeugen, sondern auch in Design und Funktionalität maßgeblich zur Effizienz und Qualität Ihrer Produkte beitragen.

x-BLOC

Composite production technology for lightweight plates and block material

Composite production technology for lightweight plates and block material

The x-BLOC thermoplastic composite production process is suitable for the rapid production of lightweight plates and blocks from a wide range of composite materials.

TOP FEATURES

-

Customised material selection

-

Lieferung innert weniger Arbeitstage

-

Customised properties

-

Simple machining

Das thermoplastische Produktionsverfahren x-CONTOUR eignet sich für die Herstellung von quasi-fertigen Halbzeugen mit spezifischer Faserorientierung.

TOP FEATURES

-

Reduced material waste

-

Realization of load paths

- High strength thanks to specific fiber orientation

-

Best price-performance for medium series sizes

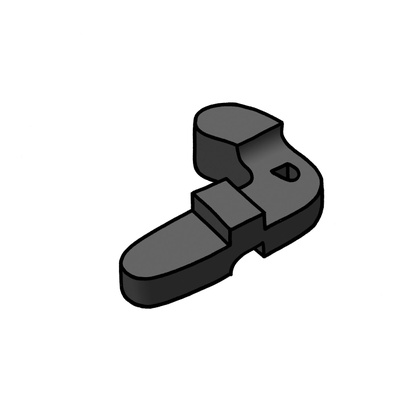

x-NET

Production technology for ready-to-install composite components

Das thermoplastische Produktionsverfahren x-NET eignet sich für die präzise Herstellung von endfertigen Composite-Bauteilen mit integrierten Funktionen und einzigartigen Oberflächen-Finishes.

TOP FEATURES

-

Unique aesthetics with bester surface quality

-

Highest functional integration

-

Complete preservation of fiber properties

-

Maximale Materialausnutzung; 0% Verschnitt

-

Minimal post-processing effort

Warum A-Comp Compression Molding?

Breite Rohmaterialauswahl und unendliche Verbundmöglichkeiten

Durch thermoplastisches Composite Compression Molding lassen sich thermoplastische High-end Verbundwerkstoffe mit PA6, PA12, PA66, PPS, PEI, PEEK, PES und TPI-Matrizes verpressen.

Kosteneffizient durch hohen Automatisierungsgrad

Compression Modeling Systeme sind in der Lage, mit einer einzigen Produktionszelle bis zu 50'000 Teile pro Jahr zu bearbeiten. Die automatisierte Massenproduktion garantiert die Qualität und Wiederholbarkeit des Teils.

Maximale Gestaltungsfreiheit

Das thermoplastische Compression Molding (Heisspress-)Verfahren kombiniert die Produktdesignfreiheit aus der Spritzgusstechnik mit der hervorragenden Festigkeit und Steifigkeit der Carbonfaser-Composites und ermöglicht eine flexible und präzise Gestaltung von Bauteilen, auch mit komplexen Geometrien ohne die mechanischen Eigenschaften zu beeinträchtigen.

Einzigartige Oberflächen-Finishes bei hervorragender Oberflächenqualität

Individuelle Konfiguration von faserverstärkten Hochleistungs-Kunststoffen für hervorragende Eigenschaften und einzigartige Oberflächen.

Herstellung von komplexen Features und 3D-Strukturen

Durch anwendungsorientierte Compression Molding Technologien lassen sich einfache bis geometrisch komplexe Komponenten mit perfekter Oberflächenbeschaffenheit und vollständig integrierten Unterfunktionen und 3D-Strukturen wie Doppelkrümmungen, T-, I- oder L-Profile, sowie netzförmige Löcher und Funktionen wie Gewinde und Verstärkungsrippen realisieren.

Feinste Toleranzen und minimaler Nachbearbeitungsaufwand

Massabweichungen nach Extrahierung des Formteils aus dem Formwerkzeug liegen innerhalb von 0,05%. Der Nachbearbeitungsaufwand bzw. Verschnitt reduziert sich daher auf ein Minimum.

Langlebigkeit und Widerstandsfähigkeit

Die daraus resultierenden Bauteile bieten eine hohe Beständigkeit gegenüber Abnutzung, Chemikalien und extremen Temperaturen, was ihre Lebensdauer verlängert.

Flexibilität

Das Verfahren eignet sich sowohl für kleinere als auch für größere Serienproduktionen.

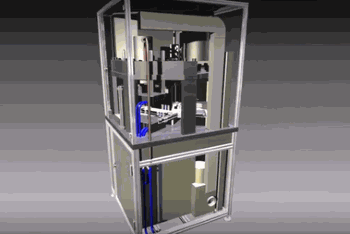

CompoMatic © Produktionszelle für Thermoplasten-Herstellung

Standard CompoMatic© A4-300 Composite Produktionssystem (anpassbar)

For our A-Comp compression molding process, we develop and design appropriate special machines and application-specific molding tools in our house-own CrossAssembly.

CompoMatic A4-300 ist CrossTEQ's standardisierte Composite Produktionszelle für das automatisierte Thermoplastpressen.

Sonderanlagen und Formwerkzeug von CrossTEQ

Für unsere Kunden entwickeln wir CompoMatic A4-300 weiter und konstruieren Sonderanlagen und massgefertigtes Formwerkzeug, um Leichtbauplatten, smarte Halbfabrikate gemäss ihren spezifischen Produkt- und Designanforderungen fertigen zu können.

- Dimensionen 2018mm*1012mm*1008mm

- Schließkraft 300kN

- Höchsttemperatur 480°C

- Maximalabmessungen der Teile 271mm*181mm

Standard CompoMatic© Composite Produktionssystem (anpassbar)

- Hohe Energieeffizienz

- Niedrige Betriebskosten

- Erhitzungs-/Kühlungsprozesse bis zu 480 °C

- Homogene Temperaturverteilung durch Präzisionsheizzonen

- Mehrere voll programmierbare Druck-Heiz-/Kühlrampen

- Einfache Bedienung durch intuitive Siemens-Simatic Control

- Ergonomische Bedienhöhe bei kompakter Bauweise

- Prozeßdatenerfassung und Speicherung

- Anpassbar gemäss Kundenanforderung

Anwendungen von A-Comp Compression Molding in diversen Branchen

A-ComP im Maschinenbau

Thermoplastische Carbonfaser Composites kombinieren die besten Materialeigenschaften von Metallen und Kunststoffen und überzeugen durch Hochleistung unter widrigsten Temperatur- und Druckbedingungen. Deshalb werden Carbonfaser verstärkte Kunststoffe immer öfter im Maschinenbau eingesetzt, wenn gängige Materialien an ihre Grenzen stossen.

Mehr erfahren

A-ComP für Luft- und Raumfahrt

Faserverbundwerkstoffe sind essenzielle Materialien in der modernen Luft- und Raumfahrtindustrie. Ihre einzigartige Kombination aus Leichtigkeit, hoher Festigkeit und Beständigkeit gegen extremste Bedingungen macht sie zu unverzichtbaren Werkstoffen für Flugzeuge, Raumfahrzeuge und andere Anwendungen in diesem Bereich.

A-Comp Recycling

Mit A-Comp hat CrossTEQ ein unkonventionelles Verfahren entwickelt, das es Industrieunternehmen ermöglicht, aus ihren Kunststoff- und Verbundwerkstoff-Abfällen auf wirtschaftliche und ökologische Weise einen Mehrwert zurückzugewinnen.

A-Comp für Uhren und Schmuck

Durch innovative Faserverbund-Mixes produziert CrossTEQ mit A-ComP hochwertige Premium Produkte wie Uhren, Schmuck und Sonnenbrillen. Premium Composite Produkte von CrossTEQ zeichnen sich aus durch einzigartige Oberflächen-Finishes bei hervorragender Oberflächenqualität.

A-Comp im Sport und Outdoor-Bereich

A-ComP ermöglicht einen hohen Grad an Funktionsintegration und somit die Substitution von strukturellen Aluminiumteilen, was in einer Nettogewichtseinsparung von bis zu 50% resultiert. Aufgrund ihres äusserst leichten Gewichts eignen sich thermoplastische Faserverbundwerkstoffe optimal für Sport-, Motorsport- und Outdoor Applikationen.