CrossComposite von CrossTEQ

Mit uns realisieren Sie innovative Composite-Materialien und leistungsstarke Leichtbauteile für anspruchsvolle Branchen wie Maschinenbau, Luft- und Raumfahrt, Medizintechnik und Luxusgüter.

Neue Masstäbe in Composites: Faserverbundbauteile von CrossTEQ

Ob Prototyp oder Serie, ob Carbon, Glas, Basalt- oder Naturfasern – die CrossTEQ AG fertigt Composite-Bauteile in höchster Präzision. Wir setzen Ihre Ideen und Pläne nahtlos bis zur Produktionsreife um.

Unsere langjährige Erfahrung, gepaart mit Innovationskraft und Vielseitigkeit, garantiert kompromisslose Qualität – individuell auf Ihre Bedürfnisse abgestimmt.

Innovative Materialien für Ihr Leichtbauprojekt

Wir bieten eine vielfältige Auswahl an Fasern und Polymeren, die eine individuelle Gestaltung von Oberflächen ermöglicht und höchste Anforderungen an Ästhetik und Funktionalität erfüllen.

So entstehen leistungsstarke Leichtbauteile mit optimalen Materialeigenschaften und einzigartige Oberflächen-Finishes, die perfekt auf Ihre Bedürfnisse und Ansprüche abgestimmt sind.

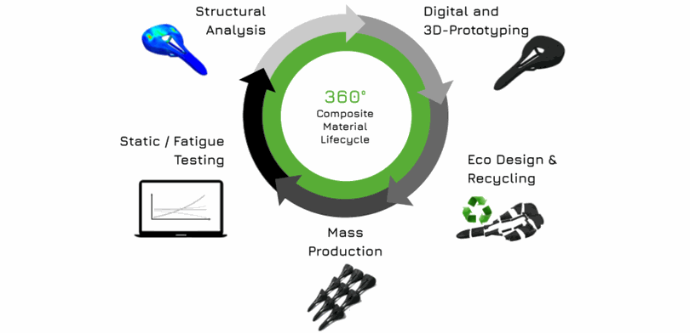

Full Composite Material Lifecycle

Unsere Leistungen umfassen alle Schritte zur erfolgreichen Umsetzung von Composite-Projekten: Von der Faserverbund-Konfiguration über das Material Design bis hin zur Formteil-Fertigung.

Dabei entwickeln wir maßgeschneiderte Lösungen, die exakt auf Ihre mechanischen, physikalischen und tribologischen Anforderungen abgestimmt sind.

Bauteile und Strukturen

- Einbaufertige Präzisionsteile

- Platten- und Blockmaterial

- Kontur-nahe Halbfabrikate

- Lastpfade

- Gewinde

- Verstärkungsrippen

- Bohrungen

- Lagersitze

> Fasern

- Carbonfaser (CFK)

- Basaltfaser

- Glasfaser

- Naturfaser

- Textilfasern

- Speziallösungen auf Anfrage

Hervorragende Materialeigenschaften und einzigartige Oberflächen

Durch die Kombination von unterschiedlichen Faser- und Matrixmaterialien erzielen sie herausragende mechanische Eigenschaften, die speziell für anspruchsvolle Anwendungen in verschiedenen Industrien entwickelt wurden.

Diese Verbundwerkstoffe bieten eine hervorragende Anpassungsfähigkeit, hohe Schlagfestigkeit und eine beeindruckende Thermostabilität, was sie zur idealen Wahl für technische und industrielle Anwendungen macht, bei denen Leistung und Langlebigkeit entscheidend sind.

> Leichtgewicht

> Festigkeit / Steifigkeit

> Hervorragende Tribologie

> Temperaturbeständigkeit

> UV-stabil

> Zähigkeit / Dämpfverhalten

> Röntgendurchlässig

> Bio-kompatibel

Entdecken Sie unsere Leistungen

Kosteneffiziente Fertigung von leistungsstarken Leichtbauteilen

Durch den gezielten Einsatz fortschrittlicher Fertigungsverfahren optimieren wir sowohl die Materialnutzung als auch die Produktionsprozesse, um hochwertige Composite-Komponenten zu wettbewerbsfähigen Preisen zu liefern.

So bieten wir maßgeschneiderte Lösungen, die sowohl in der Leistung als auch in den Kosten überzeugen.

Produktentwicklung

Die Entwicklung von Produkten aus Verbundwerkstoffen ist ein Balanceakt zwischen Innovation, Präzision und Wirtschaftlichkeit.

Wir unterstützen Sie dabei, Ihre Ideen in hochwertige Composite-Lösungen zu verwandeln, die nicht nur durch technische Exzellenz, sondern auch durch Nachhaltigkeit und Langlebigkeit überzeugen. Ob Prototypen, optimierte Serienprodukte oder zukunftsweisende Konzepte – mit unserer Expertise schaffen wir die Grundlage für Ihren Erfolg in anspruchsvollen Märkten.

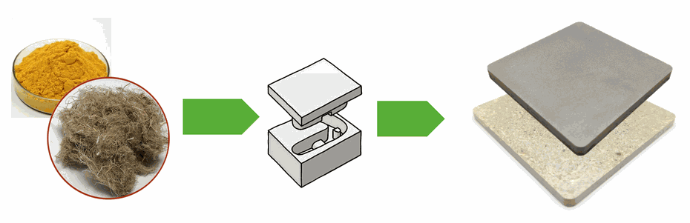

Composite Recycling

Bei CrossComposite setzen wir auf vollständig recycelbare Composite-Bauteile, die höchste Leistungsfähigkeit mit Umweltbewusstsein vereinen.

Unsere Lösungen bieten nicht nur innovative Materialeigenschaften, sondern tragen auch aktiv zu einer nachhaltigeren Zukunft bei, indem sie Ressourcen schonen und Kreislaufwirtschaft fördern.

Auswahl an Projekten und Erfolgsgeschichten

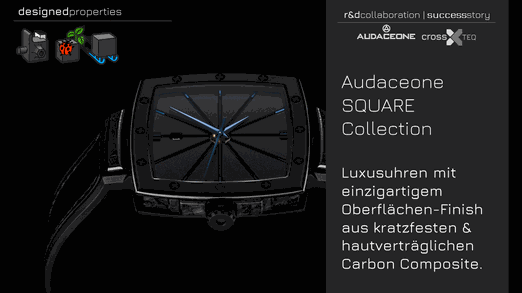

SCRATCH-RESISTANT AND SKIN-FRIENDLY WITH A UNIQUE SURFACE FINISH

Audauceone SQUARE Carbon Composite Watch Case from CrossTEQ

Jetzt lesen

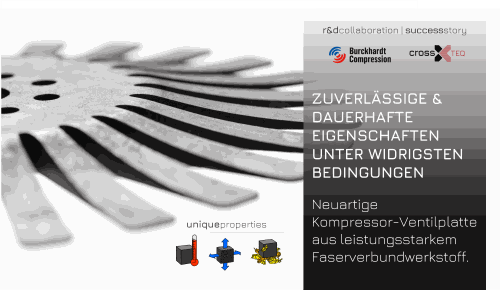

RELIABLE AND DURABLE MATERIAL PROPERTIES

R&D Collab: Compressor Valve Plate from CrossTEQ AG and Burckhardt Compression AG

Jetzt lesen

Wir sind Ihr Partner für innovative Leichtbautechnologie

CrossTEQ ist Ihr Experte für innovative Leichtbautechnologie. Mit unserer umfassenden Expertise in unterschiedlichsten Composite-Verfahren – von Formpressen (Compression Molding) über RTM (Resin Transfer Molding) bis hin zu thermoplastischen Verarbeitungstechniken – unterstützen wir Sie bei Ihrem Leichtbauprojekt.

Mit unserem eigens entwickelten, automatisierten Formpressverfahren A-Comp setzen wir neue Massstäbe: Es ermöglicht eine kosteneffiziente Fertigung geometrisch komplexer Bauteile, die gleichzeitig höchste Performance bieten.

« CrossTEQ bringt eine frische Brise in die Composite-Szene und verdient es, angehört zu werden – auch und gerade von den Grossen der Branche. »

Sie suchen innovative Materialen für Ihr Leichtbauprojekt?

Durch intelligentes Material Design und mit der richtigen Produktionstechnologie erzielen wir optimale Materialeigenschaften und einzigartige Oberflächen für Ihr Bauteil. Lassen Sie sich jetzt beraten.