Leichtbauplatten und innovatives Rohmaterial schnell geliefert

Sie suchen leistungsstarkes und ultra-leichtes Roh- oder Blockmaterial?

Teilen Sie uns Ihre mechanischen und physikalischen Materialanforderungen mit; wir liefern Ihr Rohmaterial innert weniger Tagen.

Top-Features of x-BLOC composite panels and raw material

Customized material selection

Delivery within a few working days

Customized properties

(stiffness/ strength/ fiber orientation)

Simple, machining post-processing possible

(Milling/ Turning/ Drilling)

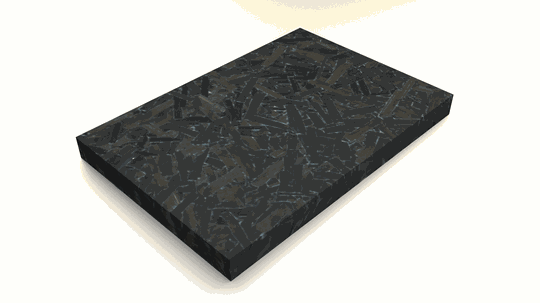

x-BLOC Compression Molding Technology for the cost-efficient production of lightweight fiber composite plates

In the x-BLOC Compression Molding process, the cut chips are scattered into a mold. The tool is then placed in the compression molding machine and pressed into the desired shape in various process phases.

The entire process is controlled by pressure and temperature parameters precisely matched to the mold and mold content.

For our composite compression molding technologies (x-Technologies), we develop and design appropriate special machines and application-specific molds.

x-BLOC composite production process

STEP 1

Preparation

The composite material is manufactured according to the required specifications and material properties.

STEP 2

Processing

With a standardized block mold a composite block is produced.

STEP 3

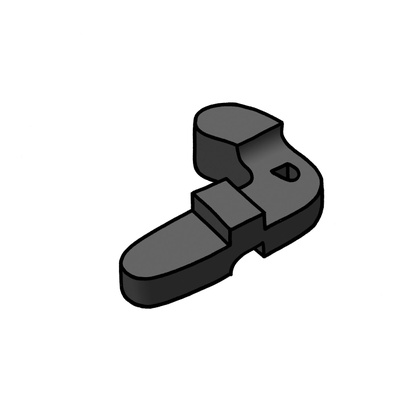

Extraction

A composite blank is released from the block by means of waterjet cutting or milling from the block.

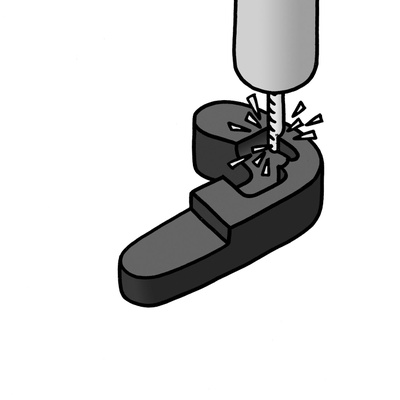

STEP 4

Post-processing

The block material is easily refinished using machining processes such as milling and turning.

STEP 5

Finishing

After surface polishing or other finishing methods, the part is fully manufactured and ready for testing and packaging.

Die CrossComposite Technologies in der Übersicht