Development and construction of assemblies

Wir entwickeln clevere Lösungsansätze für das Ramp-up Ihres Produktes unter Berücksichtigung seiner technischen, wirtschaftlichen und ökologischen Tragbarkeit. Kontaktieren Sie uns jetzt!

Unsere Entwicklungsdienstleistungen im Überblick

Whether mechanical, medical or electrical engineering - CrossTEQ AG takes over development and design tasks for you. From the first consultation, our project managers reliably accompany your product from concept development to market success. We always take into account economic, technical and ecological requirements. We plan quality and processes individually.

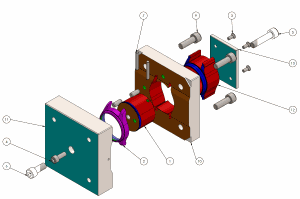

We design entirely in 3D, based on your designs.

Wir setzen auf modernste 3D-Konstruktionstechnologie, um Ihre Ideen zum Leben zu erwecken. Basierend auf Ihren Entwürfen entwickeln wir detailgenaue, vollständig digitale 3D-Modelle, die eine präzise Planung und Umsetzung ermöglichen. So stellen wir sicher, dass Ihre Visionen in jeder Phase des Projekts optimal realisiert werden.

Wir erstellen Konstruktionszeichnungen basierend auf Ihren 3D-Modellen.

Ausgehend von Ihren 3D-Modellen erstellen wir präzise und detaillierte Konstruktionszeichnungen, die als Grundlage für eine reibungslose Fertigung dienen. Diese Zeichnungen gewährleisten eine klare Kommunikation aller technischen Anforderungen und bieten eine perfekte Abstimmung für alle nachfolgenden Arbeitsschritte..

We prepare the project based on your design drawings.

Auf Grundlage Ihrer Konstruktionszeichnungen bereiten wir das Projekt sorgfältig vor. Dabei stellen wir sicher, dass alle technischen Details berücksichtigt und die Voraussetzungen für eine reibungslose Umsetzung geschaffen werden. So garantieren wir eine effiziente und präzise Projektabwicklung von Anfang an.

How we develop and design assemblies and products

Im Team und in enger Kollaboration mit unseren Forschungs- und Entwicklungspartnern nutzen wir dafür strukturierte Methoden als Framework des kreativen und zugleich pragmatischen Schaffens.

Communication

Agilität und Kollaboration sind uns wichtig. Wir schätzen den transparenten und dynamischen Austausch mit unseren Kunden, Lieferanten und Mitarbeitern, um auch auf sich ändernde Anforderungen gezielt und effektiv reagieren und die besten Produkte für Sie realisieren zu können.

Vision

Bereits in der Entwicklungsphase machen wir uns Überlegungen zu Reparierbarkeit, Optimierungen und Weiterentwicklungen Ihres Produktes. Wir planen sein Ramp-up vom Blickpunkt des Automatisierungspotenzials und dessen wirtschaftlicher Skalierbarkeit.

Data & Security

Wir dokumentieren und überwachen konsequent sämtliche Daten und alle Produktionsprozesse auf unserer hochsicheren IT-Infrastruktur. Dadurch erkennen wir Fehler und Risiken sofort und können Abweichungen lückenlos zurückführen.

Co-Engineering

Sie profitieren von einer jahrelangen Erfahrung in der Baugruppenentwicklung und Konstruktion für renommierte Unternehmen in der Medizintechnik, dank der engen Partnerschaft mit unserem Schwesterunternehmen Getronic Engineering AG.

Concepts and feasibility studies

Wir entwickeln kundenspezifische Lösungsansätze und clevere Konzepte für das Ramp-up Ihres Produkts.

Von der Auswahl der Rohmaterialien und Baukomponenten, über zum Design, hin zu Prozessentscheidungen. Wir helfen Ihnen die richtigen Entscheidungen unter Betrachtung der technischen und wirtschaftlichen Tragbarkeit Ihres Produktes zu treffen.

Bereits in der Entwicklungsphase machen wir uns Überlegungen zu Prozessoptimierungen und Weiterentwicklungen Ihres Produktes. Wir planen sein Ramp-up vom Blickpunkt des Automatisierungspotenzials und dessen wirtschaftlicher Skalierbarkeit.

Basierend auf systematischen Machbarkeitsüberlegungen und Ihren spezifischen Vorgaben, erstellen wir Produktanforderungskataloge. Unter Berücksichtigung dieser Anforderungskataloge erarbeiten und bewerten wir Konzepte.

Nebst der Funktion und Leistungsfähigkeit Ihres Produktes, berücksichtigen wir auch dessen ökologische (Recycling-Fähigkeit) und sozial-gesellschaftliche Tragbarkeit: Die CrossTEQ AG und ihre Divisionen verpflichten sich dem Dodd-Frank Act (1502, USA); so nutzen wir für unsere Produktion keine Konfliktmineralien von der Demokratischen Republik Kongo (DRC) oder angrenzenden Ländern für unsere Produktion.

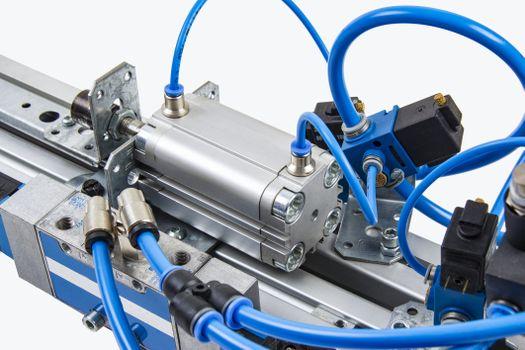

Construction of assemblies and plants

Our technical designers transform concepts into digital components and assemblies in a timely manner and design electromechanical devices and systems according to their quality and functional requirements.

The SolidWorks CAD platform enables our designers to create detailed models in the process. The creation of fit-for-purpose manufacturing data and drawings closes the gap between digital and physical product.

In our in-house 3D printing farm, we realize additively manufactured physical prototypes (and small series, individual, special and spare parts) quickly and flexibly for this purpose.

Detailed assembly drawings and digitally documented modular parts lists are used for work preparation and material requirements determination. As well as the procurement of components and spare parts and price calculation.

Für die Herstellung Ihrer Baugruppen und Geräte wählen oder entwickeln und produzieren wir die geeigneten Betriebsmittel, Werkzeuge und Montagevorrichtungen.

Analysen und Produktoptimierung

Während der Produkt-, bzw. Baugruppenentwicklung machen sich unsere Ingenieure und Projektleiter Überlegungen zur Reparierbarkeit und Weiterentwicklungen. Während der Entwurfs- und Konstruktionsphase bedeutet das vor allem, dass wir jede Baugruppe technisch individuell und systemisch unabhängig vom Endprodukt betrachten, ohne das Gesamtsystem aus dem Fokus zu verlieren.

Reparierbarkeit der Baugruppe im Blick

- Vereinfacht die Planung komplexer Gesamtsysteme.

- Bei Defekten muss nicht das gesamte Gerät zerlegt oder gar ausgemustert, sondern nur einzelne Baugruppen ersetzt werden.

- Ermöglicht eine flexiblere und gezieltere Produktionsplanung, wenn nur einzelne kleinere Baugruppen montiert, anstatt die komplette Anlagen Teil für Teil aufgebaut werden müssen.

Preparation & Equipment

Ausführliche Baugruppenzeichnungen und digital-dokumentierte Baukastenstücklisten dienen der Arbeitsvorbereitung und Materialbedarfsermittlung, sowie der Bau- und Ersatzteilbeschaffung und Preiskalkulation. Für die Herstellung Ihrer Baugruppen und Geräte wählen oder entwickeln und produzieren wir die geeigneten Betriebsmittel, Werkzeuge und Montagevorrichtungen.