A-Comp compression molding for the automated production of complex lightweight structures made of high-performance composites

Due to their excellent material properties thermoplastic composites are used where metals such as steel or titanium are too heavy and plastics too weak.

However, today fiber composite processes for surfaces are comparatively mature and widely established in numerous applications such as aircraft and vehicle structures. Composite technologies for more complex structural elements such as connecting or load introduction elements, on the other hand, are as yet less mature. Light and mechanical engineering are still waiting for scalable solutions for their high-performance applications.

CrossTEQ has developed an automated, final-contour manufacturing process that enables the targeted use of mechanical properties in complex lightweight structures.

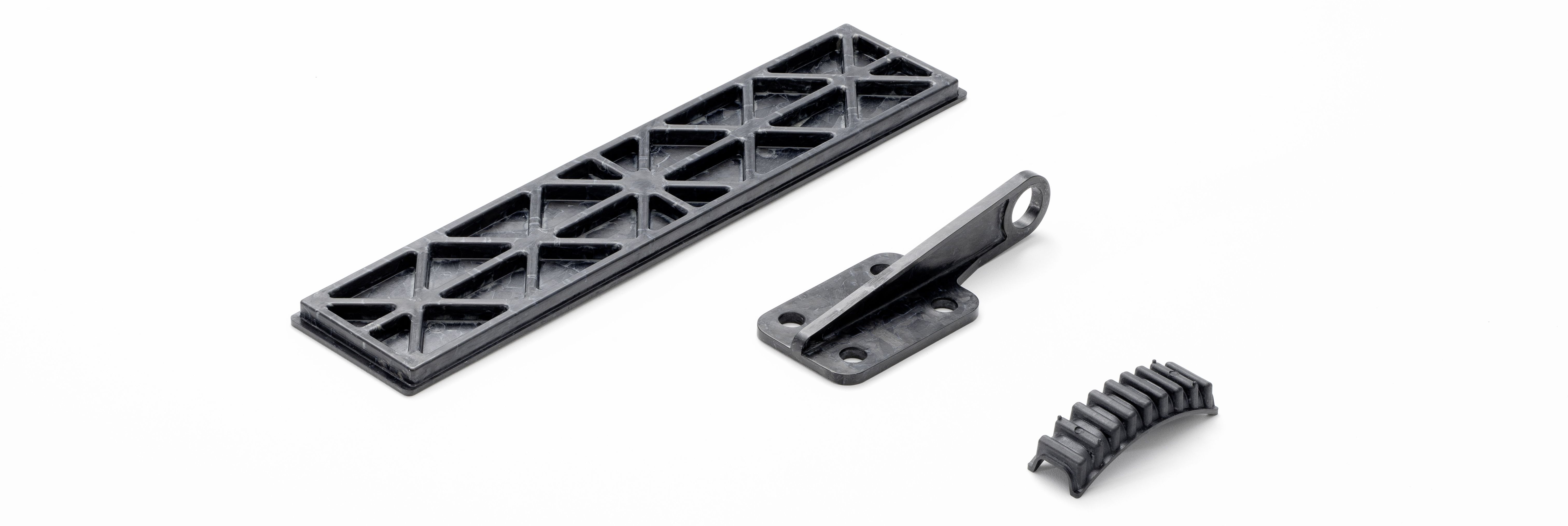

Fasteners: Where even steel and titanium reach their limits

Due to their geometric complexity, metallic materials such as steel, titanium or aluminum are still mostly used for fasteners such as clips, brackets or hinges. However, these materials have significant disadvantages in lightweight applications:

Steel: Heavy weight due to high density

Titanium: High material and processing costs due to low availability of raw material

Alluminium: High process effort to build up corrosion protection against surrounding composite structures

Final contour-accurate manufacturing process for complex lightweight structures with excellent mechanical properties

With the aim of producing complex and at the same time high-performance lightweight structures in an automated manner, CrossTEQ has developed its own final contour accurate composite process that optimizes the subsequent processes, material waste and thus also the costs during component production to a minimum.

Finest tolerances, minimal post-processing effort

Weight reduction through complete elimination of metallic inserts

Maximum material utilization, 0% waste

Automated, scalable production

Complete preservation of fiber properties

A-Comp: Excellent mechanical properties for high-performance applications

Image: Final contour accurate valve plate for large reciprocating compressors, manufactured using the A-Comp process..

Image: Final contour accurate valve plate for large reciprocating compressors, manufactured using the A-Comp process..

With A-Comp Compression Molding, CrossTEQ combines the product design freedom from injection molding with the outstanding properties of thermoplastic composites, thus offering the light and mechanical engineering sectors a scalable production process for the manufacture of precision-finish fasteners and profiles made from fiber-reinforced high-performance plastics such as PEEK, PSU, PPSU or PEI.

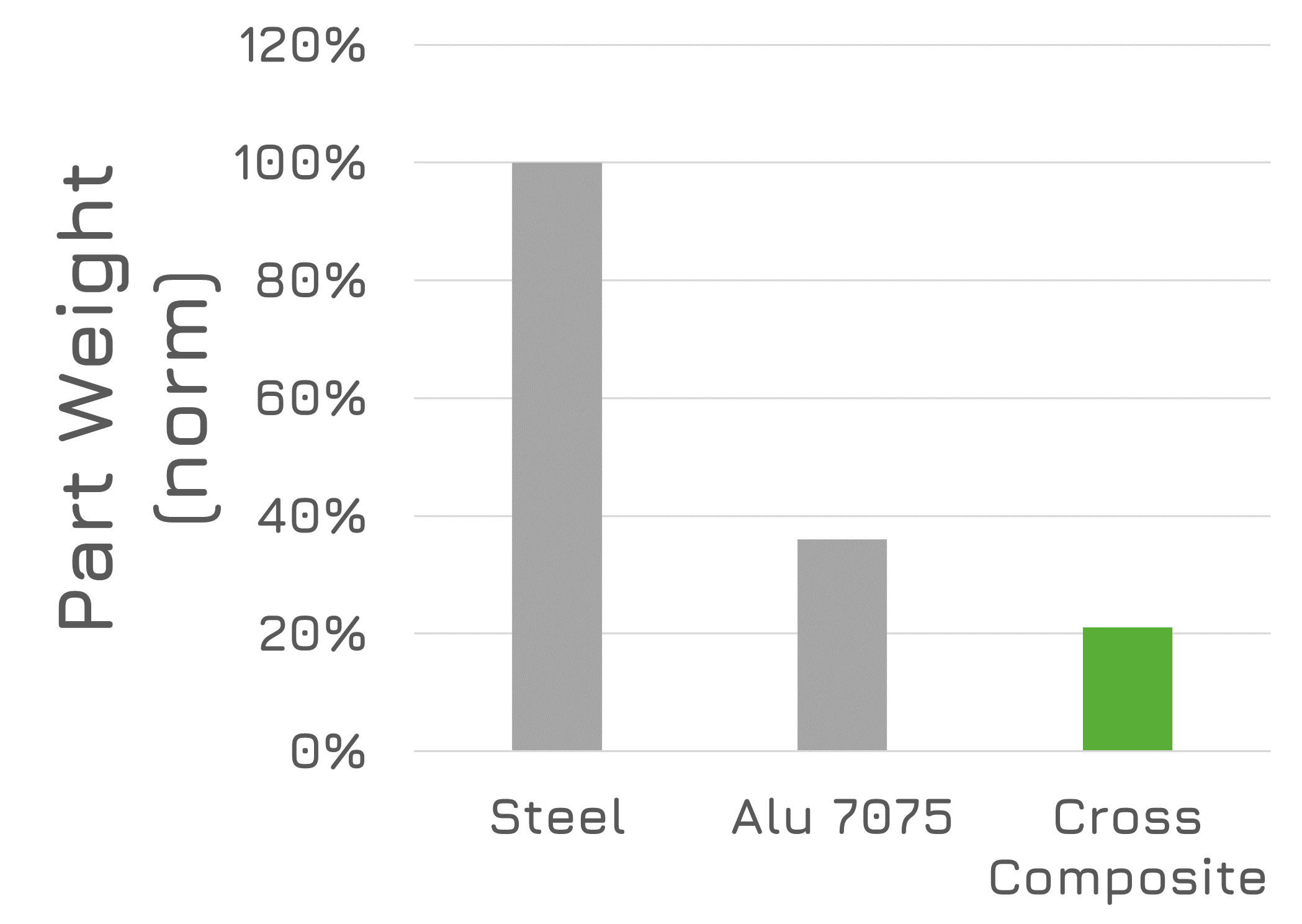

Significant weight reduction

The thermoplastic lightweight components from CrossTEQ, achieve identical mechanical properties to metals - but with a massive reduction in weight:

Read about it in our latest R&D success story

Significantly improved efficiency in large reciprocating compressors due to ultra-light and durable composite valve plate - manufactured with A-Comp.

Versatile, material-specific properties

CrossTEQ is specialized in the Construction and design of geometrically complex component geometries with discontinuous fiber architecture.

State-of-the-art FEM tools based on classical laminate theory (CLT) and developed specifically for discontinuous fiber composites (DFC) allow us to precisley predict material and component properties in this process.

Are you looking for a composites partner for complex and high-performance components?

For our partners, we continuously develop new, product-oriented composite technologies and the corresponding equipment and molding tools. Contact us.