Wieso Function-Testing in der Baugruppenmontage?

Der Zweck des Funktionstests (Function Test) ist es, die grundsätzliche Funktion aller Elektronikkomponenten sowie deren Zusammenspiel systematisch zu prüfen und dauerhaft sicherzustellen.

Mit Hilfe des Funktionstests prüft CrossTEQ systematisch und zuverlässig die Gesamt- oder Teilfunktion einer Baugruppe oder eines ganzen Systems. Der Funktionstest beinhaltet dabei sowohl die Endprüfung nach Fertigung einer Baugruppe als auch nach dem Einbau der jeweiligen Baugruppe im fertigen Gerät.

Testvoraussetzungen und Prüfungsanweisungen für Funktionstest bei CrossTEQ

Qualifikation

CrossTEQ sorgt dafür, dass das Personal in der Durchführung von Funktionstest angemessen geschult ist. Nur regelmäßig geschultes Produktionspersonal, darf den Funktionstest (und Burn-in Test sowie Factory Acceptance Test) durchführen.

Testumgebung und Vorsichtsmassnahmen

Das CrossTEQ-Qualitätspersonal (Produktionsleiter und Leiter der Fertigungstechnik) pflegt und implementiert Arbeitsanweisungen, Richtlinien zur Testumgebung sowie allfällige Vorsichtsmaßnahmen für Funktionstest (insbesondere bei elektrostatisch empfindlichen Geräten!).

Testing Software

Die Test-Anwendungssoftware führt den Tester durch die verschiedenen Testschritte und führt den automatisierten Testabschnitt aus, wo dies möglich ist. Die Testanwendung dokumentiert und erstellt digitale Testberichte, welcher der Tester unterschreiben muss.

Berichte

Abweichungen/Mängel sind auf dem Prüfbericht zu vermerken. Etwaige Korrekturmaßnahmen und die folgenden Regressionstests sind auf Aufforderung der Testanwendungssoftware detailliert zu beschreiben.

Gemäss der Liefervereinbarung archiviert CrossTEQ Berichte als Teil des Device History Record (DHR). Jeder Bericht muss anhand der Teile-Identifikationsnummer und der Seriennummer auf das Bauteil rückführbar sein.

Verantwortung

Erst nachdem die Prüfung erfolgreich ist, wird die Montage der Baugruppe oder des Geräts abgeschlossen. Unser Qualitätspersonal führt den Quality Assurance (QA) Buyoff für die Produktfreigabe durch und bestätigt die ordnungsgemäße Herstellung, Prüfung und Berichterstattung durch elektronische Unterzeichnung, bevor an den Kunden geliefert wird.

Anwendungen und Beispiele für Funktionstests

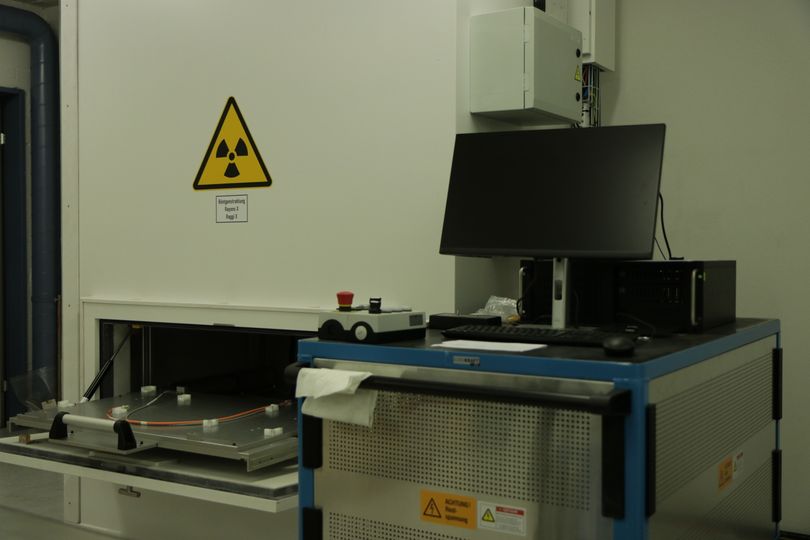

Röntgenbild-Funktionstests bei Strahlungstherapie-Imager

Bei diesem Funktionstest testen wir die Aufnahme von Röntgenbildern in der Dunkelkammer, mit dem Ziel, dabei Fehler zu entdecken, die durch das Zusammenspiel der Komponenten verursacht werden.

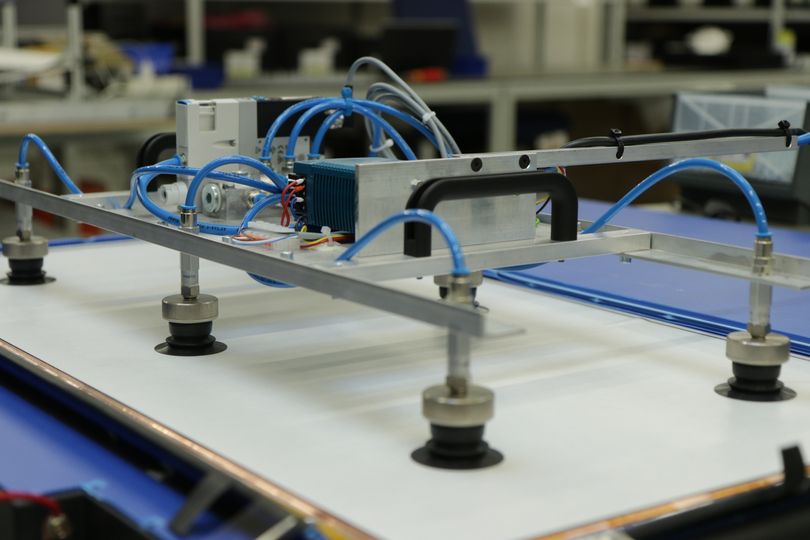

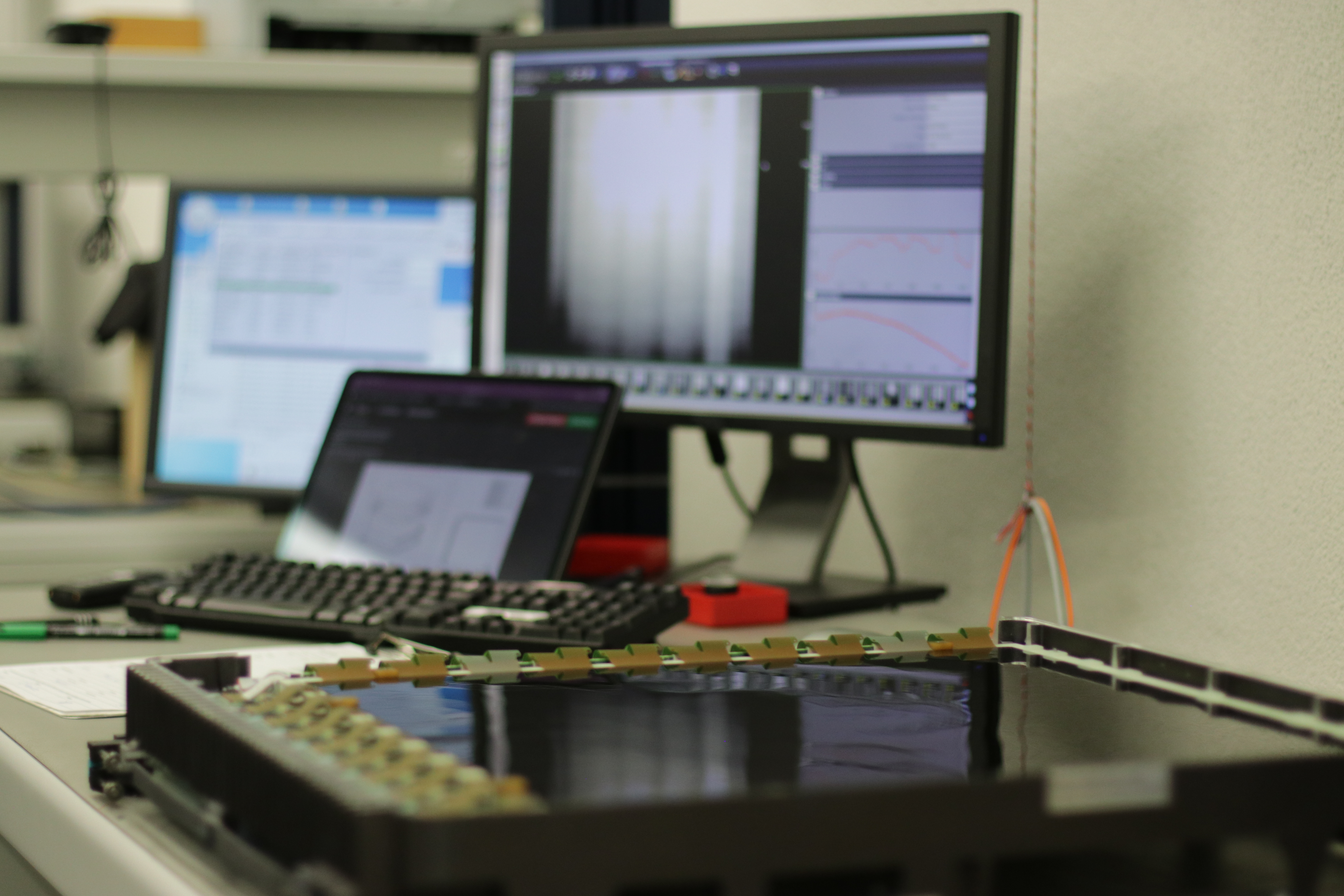

Funktionstest eines großflächigen, hochsensiblen Bildsensors bei der Wareneingangskontrolle

Unser Qualitätspersonal ist besonders geschult für die Prüfung und Montage grossflächiger und sensibler Sensor-Panels, da bei unsauberer Handhabung das Glas an den Frame-Komponenten anschlagen oder Flexkabel an den PCBs hängen bleiben und beschädigt werden können.

Bei der Warenannanhme solcher Panels werden zuerst Arbeitsplatz und Vorrichtungen mit ionisierter Druckluft gereinigt und die Geräteerdung sichergestellt. Vor dem eigentlichen Panel-Funktionstest wird zuerst die Vakuums-Handlingsvorrichtung geprüft. Dafür wird der Bildsensor mit der Vorrichtung aus der Verpackung entnommen und in Bildsensor Testvorrichtung eingelegt. Nachdem der Bildsensor in die Testvorrichtung eingelegt wurde, wird dieser sauber an den PCBs ausgerichtet und alle Flexkabel in Klemmen eingesteckt und geschlossen. Der Bildsensor wird möglichst lichtdicht abgedeckt, wenn er an die Teststation angeschlossen und die Prüfung durchgeführt wird.

Bei CrossTEQ sind wir spezialisiert auf die anspruchsvolle Qualitätssicherung von elektrostatisch empfindlichen Baugruppen und Geräten.

Wir montieren, testen und justieren komplexe Baugruppen und hochsensible Mikroelektronik mit dauerhaft höchster Präzision und Zuverlässigkeit.

Das könnte Sie auch interessieren

Burn-in Testing von Baugruppen vor Anlauf der Massenproduktion

Beschleunigter Lebensdauertest zur Prüfung der Belastbarkeit von Komponenten, Baugruppen oder Komplettgeräten im Dauerbetrieb.

Anwendungsbeispiel von CrossTEQ: Frequente Aufnahme von Dunkelfeldbilder und Erzeugung von Driftbilder mit Radiotherapie-Imager während 48 Stunden.

Finaler Factory Acceptance Test (FAT)

Zur Validierung des Gerätebetriebs und Sicherstellung, dass Bestellspezifikationen und Qualitäts - und Funktionsanforderungen des Kunden erfüllt wurden.

Anwendungsbeispiel bei CrossTEQ: Endabnahmetest (Röntgentest) zur Aufnahme von Röntgentestbildern mit Radiotherapie-Imagers